Competitive price continuous plastic pyrolysis plant used tires changers crude oil refinery machine

-

Supplier: Beston (Henan) Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms Alica Luo -

Price: $39000.00 /set -

Min. Order: 1 set

| Working Form: | Continuous; | Packaging Detail: | Standard Export Packing; |

| Service Life: | 5-8Years; | Port: | China Main Port; |

| Payment Terms: | L/C,T/T,Western Union; | Place of Origin: | Henan China; |

| Dimension(L*W*H): | 40M*10M*10M area; | Reactor Steel Thickness: | 16mm; |

| Condition: | New; | Reactor Rotatable Speed: | 0.4-0.8turn/minute; |

| Warranty: | 12 monthes; | After-sales Service Provided: | Field installation, commissioning and training; |

| Name: | Waste plastic pyrolysis plant; | Supply Ability: | 245 Set/Sets per Year Competitive price continuous plastic pyrolysis plant used tires; |

| 24Hours Pyrolysis Capacity: | 16-20T; | Reactor Materail: | Q245R or Q345R Boiler Steel Plate; |

| Brand Name: | Beston; | Fuel: | Coal, Gas, Oil, Wood; |

| Cooling Sytem: | Water Cooling; | Certification: | CE, ISO; |

| Reactor Size: | D2800 x L7100mm; |

competitive price continuous plastic pyrolysis plant

3D Drawing Of Pyrolysis Plant

Technical Sepcification

Model | BLJ-6 | BLJ-10 | BLL-16 | BLL-30 | BLL-40 | BLL-50 |

Daily capacity | 6MT | 10MT | 20MT | 30MT | 40MT | 50MT |

Working method | Batch | Semi-continuous | Fully continuous | |||

Operating pressure | Constant pressure | |||||

Reactor rotate speed | 0.4turn/minute | Not rotary type | ||||

Total power | 24kw | 30kw | 54kw | 53.6kw | 62kw | 84kw |

Reactor size | D2.2*L 5.1m | D2.8*L6.2 m | D2.8 *L7.1 m | L12.5*W2.2*H2.5m | L12.5*W2.2*H2.5m | L12.5*W2.2*H2.5m |

Space for machine(L*W*H) | 20*10*10 m | 25*15*10 m | 25*15*10 m | 20*15*10m | 33*15*10m | 33*15*10m |

Main Features of Pyrolysis Plant

Safety

1. With an auto welding machine for the reactor, it can not only greatly improve working efficiency of pyrolysis plant, but also guarantee the quality of welding seam, thus avoid explosion caused by gas leak.

2. Professional heating treatment and x-ray detection chamber are especially for welding.

3. Professional thermometer, pressure gauge and safety valve.

4. It is dangerous to burn exhaust gas (C1 to C4) without any safety measures. In our pyrolysis plant, it is transferred first through the safety device and a safety burning air muzzle. Before burning, we should ensure the safety of production.

Long service Life

1. Material: Q245R or Q345 Boiler Steel Plate, thickness 16mm.

2. Welding: Automatic welding machine with heating treatment and x-ray detection will prolong the service life of

reactor to the max.

Energy Saving

1. Well sealing for heating system, no gas leak and saving fuel.

2. The exhaust gas will be recycled for reactor heating.

Main Parts of Pyrolysis Plant

General Production of Pyolysis Plant

Raw Materials Feeding System of Pyrolysis Plant

Reactor of Scrap Plastic Pyrolysis Plant

Oil Tank of Pyrolysis Plant

Dedust System of Pyrolysis Plant

Water Cooling System of Pyrolysis Plant

Environmental Friendly

1. Well water de-dusting system can avoid black smoke in the waste plastic pyrolysis processing.

2. The exhaust gas will be recycled for heating reactor, no gas pollution

3. Every junction of the pyrolysis plant reactor is in good sealing situation with professional sealing material.

Welcome to visit our factory!

15 years manufacture supplier! competitive price continuous plastic pyrolysis plant.

-

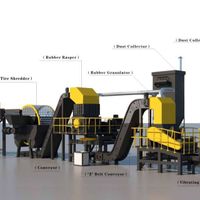

Tire recycling plant for waste recycling equipment

-

Semi-automatic waste tire recycling into rubber powder machine tire cutting machine

-

High-performance used tire recycled rubber production line rubber powder making machine tire recycling production line

-

Reclaimed rubber production equipment

-

Used tire cutting machinery, tire recycling machinery for sale

-

Factory sale 1-2 tons waste tire rubber shredder recycling plant

-

Waste tire wire separator/tire wire remover/tire wire remover

-

Zero consumption tire doubling machine used tire doubling machine for sale

-

waste tire recycling machine used tire recycling shredder factory in pakistan

-

Electric old tire recycling machine shredder waste strip waste truck tire tread sidewall cutting machine

Other Products

-

$41200.00 / set

$41200.00 / set -

$2000.00 / set

$2000.00 / set -

$10000.00 / set

$10000.00 / set